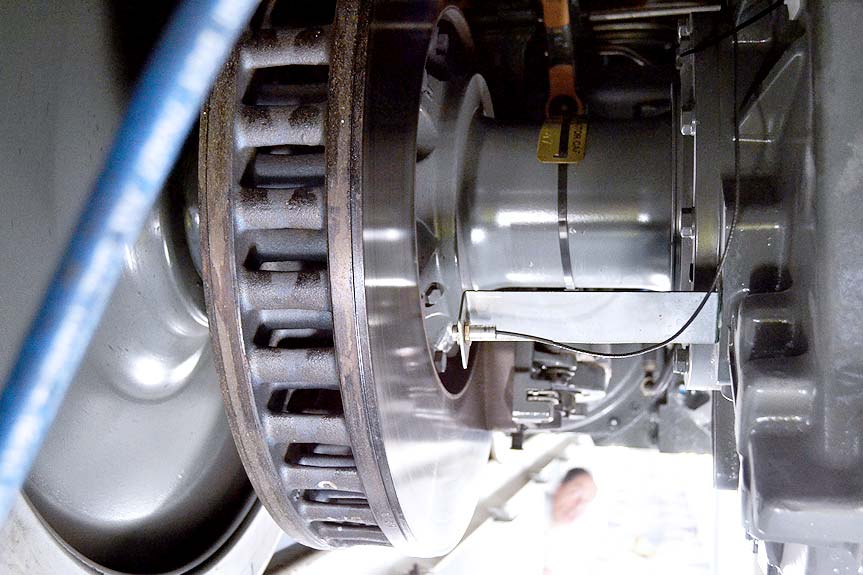

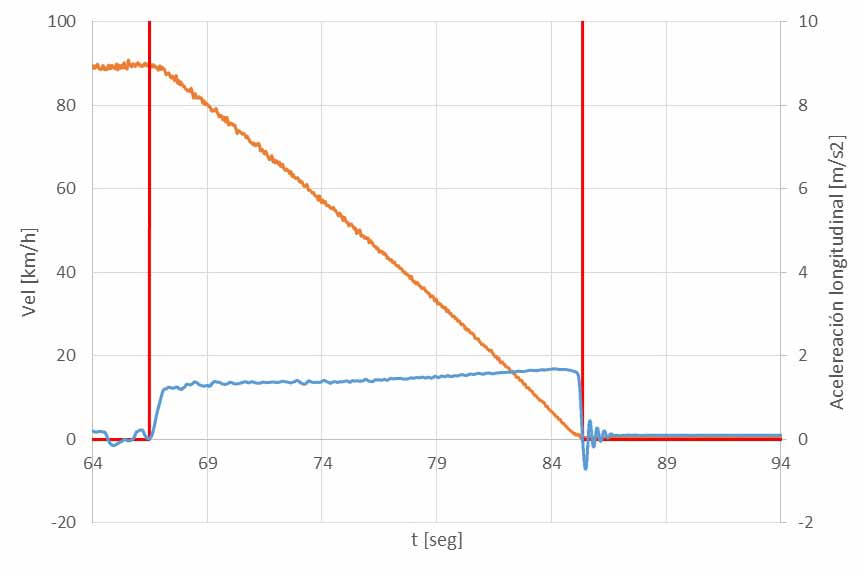

The main objective of brake testing is to determine the braking performance of railway vehicles. Braking performance may be assessed by determining stopping distances, brake weights or equivalent decelerations.

CETEST´s expertise includes the following:

- Functional requirement tests according to UIC547 and UIC540 standards

- Braking performance assessment tests according to UIC544-1 and TSI LOC&PAS standards

- Wheel slide protection tests according to EN15595:2020 standard

- Determination of braked weight percentage and braking distance according to UIC544-1 standard