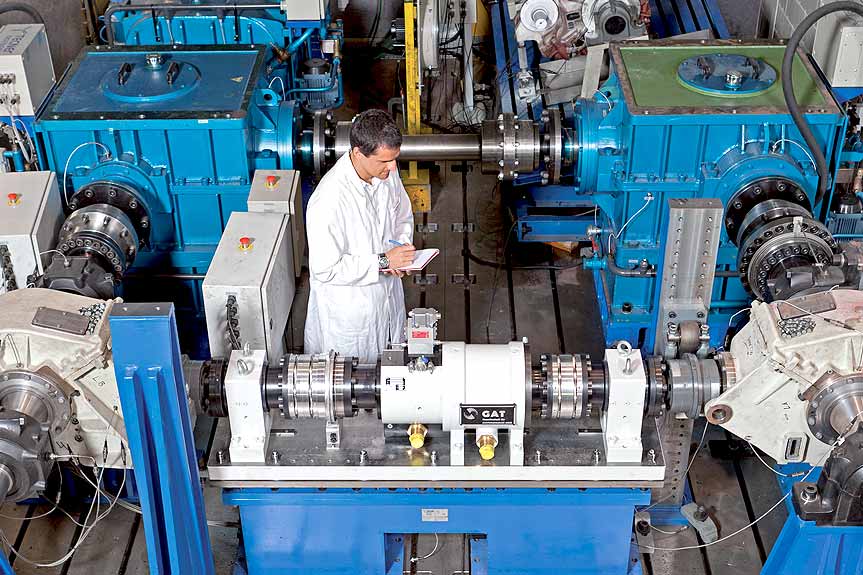

Our test benches can be adapted to different powers, speeds and torques. We can therefore run any tailor-made testing solution adapted to our client’s needs.

Some of these rigs are prepared for no-load studies and they are rotary, being able to simulate ramps and curves. The main purpose of this test is to run the gearbox with no torque while checking:

- There is a sufficient amount of oil, which is needed to dissipate the heat generated during this kind of operation.

- Oil is distributed to all moving elements inside the gearbox (mainly the bearings and gear contact).

- Initial oil and bearing temperatures for the entire speed range.

- For external oil leaking out of labyrinths, seals, etc.