We design, manage and realise structural testing according to EN 12663, APTA, PRIIA, ASME, GM RT and other international standards. CETEST can also adapt the test design to your specific requirements, including static and dynamic loads where required.

The structural design (and hence safety) of railway vehicle bodies depends on the loads they are subjected to and the characteristics of the materials they are manufactured from. These load requirements considered during the structural design and testing of the vehicle body are based on proven experience and supported by the evaluation of experimental data and published information. Here at CETEST we collaborate with you throughout the testing stage.

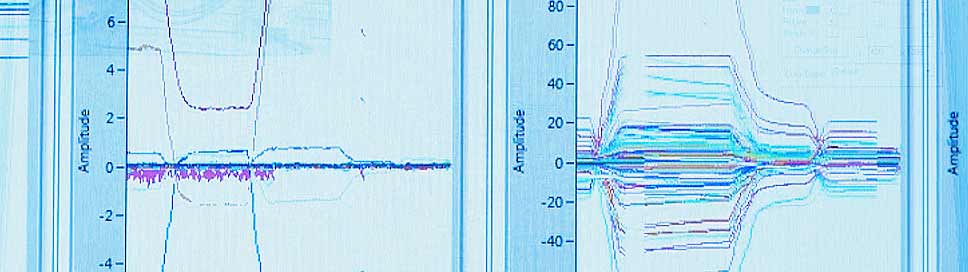

The CETEST laboratory runs several structural test rigs adapted for car body frames with different lengths, track gauges and geometries. Strain gauges and rosettes, as required, can be placed at any point around the vehicle. We have successfully completed tests while taking measurements through up to 400 channels!