Traction functionality and performance, as well as auxiliary supply operation, play a major role in the validation of new and existing rail vehicles. CETEST is a specialist in the measurement and interpretation of electric parameters. We boast a wide range of sensors and acquisition hardware and software that can be tailored to measurement needs in function of all vehicle types and test specifications.

CETEST is accredited to evaluate the traction performance and traction chain functionality of rail vehicles according to European standards TSI 1302/2014, EN 50215, EN 50163, EN 14067-4 and EN 50388, as well as National Specifications or particular requirements derived from the client’s project specifications.

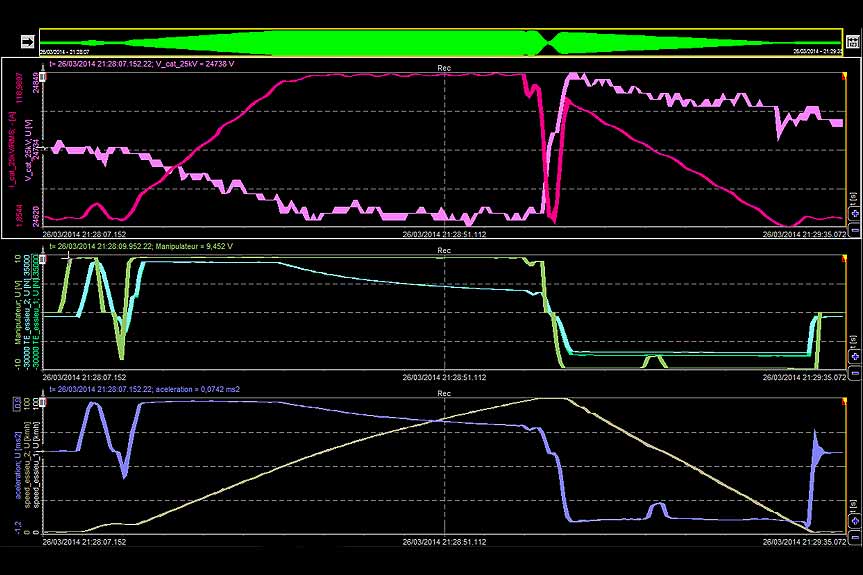

The main objective of traction tests is to evaluate the vehicle’s traction performance (effort-speed characteristic curve) in different running configurations (normal and degraded):

- Acceleration tests (from static to Vmax).

- Braking tests (from Vmax to static).

- Running resistance tests.

- Hill start tests.

- Adherence tests.

- Residual acceleration tests.

- Jerk monitoring tests.

In addition to this, traction validation also evaluates the functionality of the complete traction chain under all possible driving conditions. Hence vehicle operation and functionality are assessed whilst varying line voltage, plus line voltage interruptions, electrodynamic braking and the vehicle’s maximum power consumption at different running conditions are also evaluated.

The main sensors used during these tests include:

- Current measuring sensors: DC current clamps and AC current transformers to assess vehicle power consumption.

- Rogowski coils for AC monitoring and harmonic detection.

- Voltage probes for line voltage and traction circuit voltage measurements.

- Accelerometers and servo-accelerometers for traction performance measurements.

- Gyroscopes for vehicle orientation measurements during traction performance evaluation.

- Speed sensors: vehicle dependent (tachometers) and vehicle independent sensors (optical sensors).

- GPS for vehicle positioning evaluation and correlations.

Any combination and number of the above sensors can be connected to CETEST’s multiple data acquisition systems for optimal data recording. CETEST possesses multispeed and synchronous DAQs so they can construct flexible measurement chains quickly. Besides, CETEST has proprietary post-processing tools specifically developed in-house for optimal data treatment that can be tailored to each client’s needs.