CETEST measures the stress levels and determines the global stress history that the piece will experience during its operational life. This history is used to estimate the risk of fatigue failure by means of the cumulative damage method, also known as Miner’s and Goodman’s rules. This calculation involves comparing the measured stress levels against an S-N curve (in compliance with standards EN 1999-1-3, EN 1993-1-9 and ERRI B12/RP60).

CETEST is a specialist in extensometric on-track tests for determining stress levels in different components (bogies, car body frames or specific elements) during normal service, according to EN 13749, EN 12663 and EN 17149. This yields information which complements the static tests and is highly valuable for fatigue failure analysis or for simplified homologation due to slight modifications on the car body during the vehicle’s lifetime.

An on-track fatigue analysis provides information to complemented data obtained during static tests (e.g., identification of slightly damped modes associated with resonances). Real load scenarios created during this test can also be used to validate the design when the standards are too restrictive.

In the case of fatigue failure, the information derived from this type of test could be crucial in determining the nature of the problem and potential solutions.

CETEST has also used this test to validate slight modifications in the car body (modification of supports so that equipment can be changed, for example).

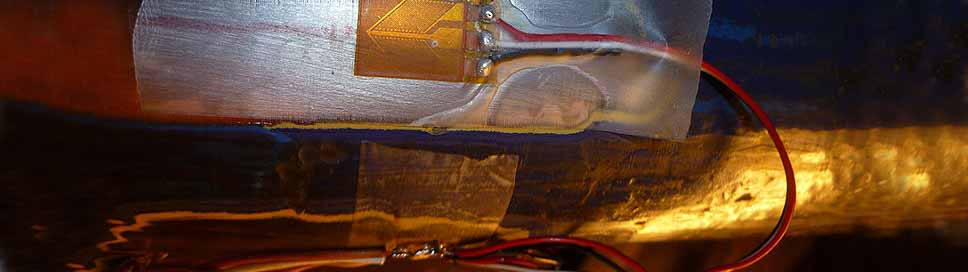

CETEST has extensive experience conducting these tests in all kinds of vehicle across the world. We offer technical support to define the most critical measurement points, as well as carrying out the actual test and assessing the fatigue performance of the tested component. Furthermore, our ample experience in this sort of measurement means we can provide the best instrumentation layout to ensure strain gauge durability and minimum instrumentation time.