This special instrumentation may be used, not only to certify new vehicles in accordance with the above standards, but also to optimise maintenance and enhance safety thanks to advanced track measurements and research into wheel/rail contact issues.

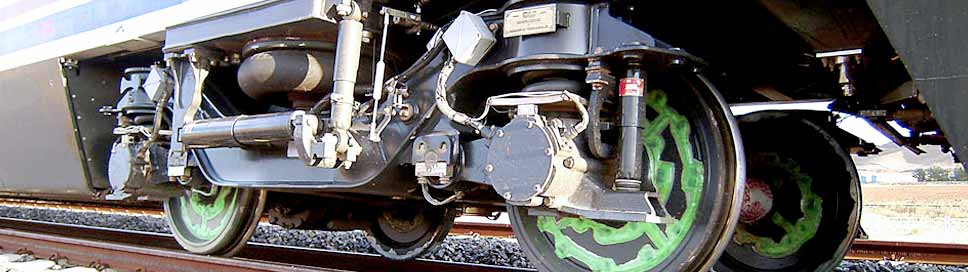

Our instrumented wheelsets are based on strain gauge instrumentation; hence contact forces can be obtained through direct measurement of the stresses experienced by the wheel without any influence from the wheel/rail contact point position. Contact forces values can be real time processed by using CETEST Data Processing Module (DPM), based on embedded hardware technologies. The real-time data obtained includes vertical, lateral and longitudinal loads as well as the wheel/rail contact point position.