Determining the cause of cracks in bogie support

Problem

Cracks appeared on the joint between the current collector support and the bogie. This implies the risk of the support falling onto the track and potentially causing a major accident.

Aim

To determine the origin of the failure. FEM calculations indicated the area did not experience any high levels of stress that could have explained the failures. Consequently, possible explanations include a fault in the hypothesis used for the FEM calculations, worse material properties or incorrect execution of the welding process.

Test proposal

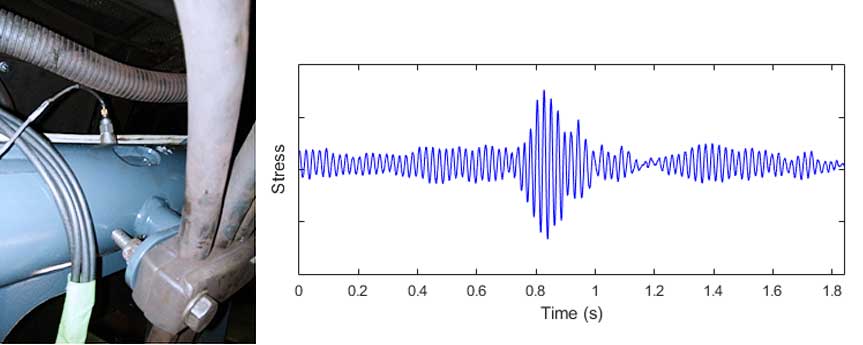

In order to determine the real loads placed on the component, a test simulating normal service conditions was proposed. The instrumentation included strain gauges to measure stress levels and accelerometers to establish excitations paths and possible resonances.

Results

Based on the test results, the support presented a vibration mode with a low natural frequency that caused most of the damage to the component.

Solution proposed

Increase the stiffness of the support in order to alter the natural frequency of the main vibration mode.